Modular switchboard systems

The Current Landscape (Before)

Traditionally, Australia’s switchboard infrastructure has relied on rigid, non-modular systems that struggled to keep up with rising power loads, safety requirements, and smart integrations. Engineers and facility managers frequently faced limitations with traditional form separation, often forced to compromise between accessibility and protection. With growing demand in data centres, industrial automation, and green energy, the gap between outdated boards and real-world needs became more evident.

The Transformation (After)

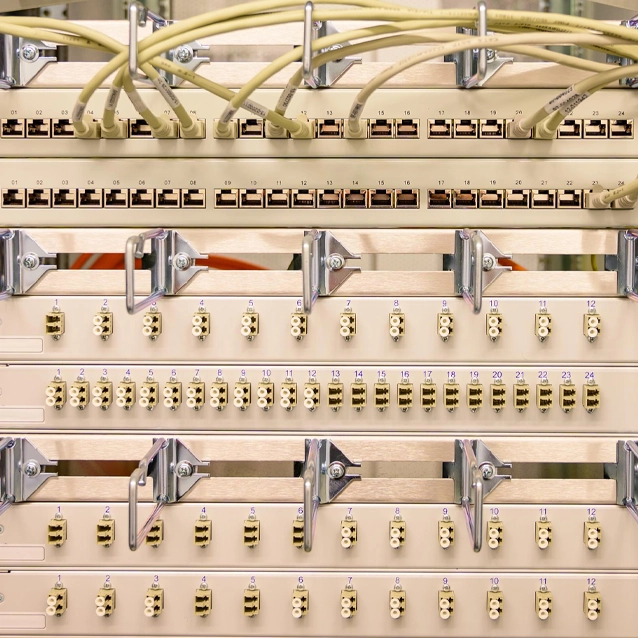

CUBIC modular switchboard systems with Form-4b separation are revolutionising Australian industrial power distribution. With full compliance to AS/NZS 61439 standards and support for high current LV systems, these panels offer a significant leap in safety, flexibility, and maintenance accessibility. Form-4b’s separation ensures each functional unit, busbar, and outgoing terminals are isolated—ideal for MCCs and critical power environments. Combined with leading modular frames like CUBIC and xEnergy, the modern modular switchboard is no longer a luxury but an industry expectation.

The Bridge: What Makes Modular Form-4b Panels the Preferred Choice?

1. True Form-4 Separation with Enhanced Safety

Form-4b modular switchboards separate functional units and terminals, minimising the risk of arc flash and ensuring maintenance without system shutdown. This is crucial in motor control centre switchboard applications, where uptime is critical.

2. CUBIC Compatibility and Flexibility

CUBIC enclosures are engineered for modularity, enabling scalable layouts for custom LV modular switchboards. Their interlocking design supports configurations from basic Form-1 to advanced Form-4b, making them highly adaptable to commercial, industrial, and energy-critical applications.

3. Built for Harsh Conditions in Australia

Designed with powder-coated finishes and IP-rated protection, CUBIC and xEnergy modular switchboards Australia-wide offer resilience in dusty, humid, or high-temperature conditions—whether in mining, renewables, or marine infrastructure.

4. Easier Compliance with AS/NZS 61439

CUBIC’s systems simplify compliance with AS/NZS 61439:2016 by pre-testing assemblies and enabling standardised layouts for consistent verification. Pro-tech Switchboards AU ensures all modular boards align with these strict standards.

5. Ideal for High Current Modular LV Systems

Modular switchboards designed with Form-4b support currents up to 6300A and multiple distribution paths, making them ideal for industries scaling operations or installing parallel sources like backup generators or solar inverters.

Frequently Asked Questions

What is the difference between Form-4a and Form-4b switchboards?

Form-4b separates terminals from functional units and busbars, offering superior protection during maintenance or failure.

Can modular switchboards be upgraded after installation?

Yes, modular systems are built for flexibility. Units can be added or swapped as load requirements change.

Are CUBIC and xEnergy compliant with Australian standards?

Yes, both systems are compatible with AS/NZS 61439 and are used widely in the Australian commercial and industrial sectors.

Author Name: Liam Carter

Position: Senior Technical Content Specialist

Company: Pro-tech Switchboards AU

Location: Melbourne, Australia

Experience: 10+ years in electrical switchboard systems, compliance engineering, and industrial automation.

Author Bio:

Senior Technical Content Specialist at Pro-tech Switchboards AU, Liam has over 10 years of experience in modular switchboard systems, grid protection, and industrial compliance. He simplifies complex electrical standards into clear, practical insights for Australia’s commercial and industrial sectors.