Powering Every Industry with Precision-Built Switchboards

Tailored switchboard solutions for mining, utilities, commercial, renewables, and more—built to perform in every environment.

Our Expertise

Solutions by Industry

Below are five industry tabs you can feature each with a one-line description tailored to Pro-Tech Switchboards’ strengths:

Mining

Rugged, high-capacity switchboards built to withstand dust, vibration and extreme temperatures on site.

Commercial

Modular power distribution for office towers, retail centers and hospitality venues designed for flexibility and scalability.

Utilities

Grid-tied switchgear with advanced metering and remote-monitoring options to ensure reliable service delivery.

Solar & Renewables

Custom solar inverter panels and hybrid switchboards optimized for photovoltaic, wind and battery storage systems.

Industrial Manufacturing

Heavy-duty control panels engineered for assembly lines, process plants and automated machinery applications.

Data Centers & IT

Precision-engineered switchboards with redundant power feeds, surge protection, and remote diagnostics to safeguard critical infrastructure.

Case Studies

Switchboards That Perform in the Real World

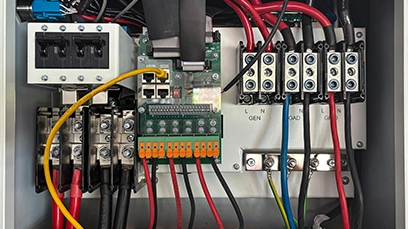

Solar & Renewables

Hybrid Power Station – Port Augusta, SA

- Challenge:

A large-scale solar and battery hybrid power station required custom-built inverter and grid-protection panels that could withstand extreme heat and support future capacity expansion.

- Our Solution:

Pro-Tech engineered IP66-rated switchboards with heat-resistant enclosures, modular copper busbars, and smart metering integration. Built and delivered in under 10 days.

- Result:

Seamless commissioning and 99.98% uptime in the first year. The scalable design now supports an additional 30% energy input from battery upgrades.

- Challenge: A large-scale solar and battery hybrid power station required custom-built inverter and grid-protection panels that could withstand extreme heat and support future capacity expansion.

- Our Solution: Pro-Tech engineered IP66-rated switchboards with heat-resistant enclosures, modular copper busbars, and smart metering integration. Built and delivered in under 10 days.

- Result: Seamless commissioning and 99.98% uptime in the first year. The scalable design now supports an additional 30% energy input from battery upgrades.

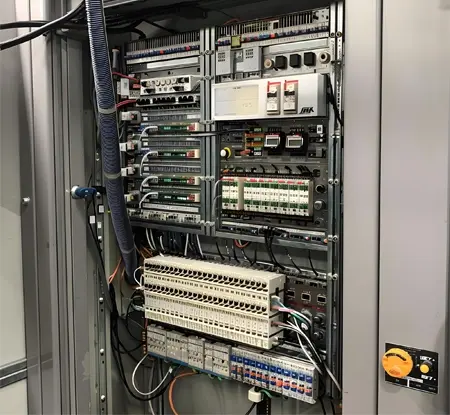

Data Centres

Edge Computing Facility – Melbourne VIC

- Challenge:

A Tier 3 edge data center needed redundant power feeds, isolated power zones, and real-time monitoring to meet strict uptime and compliance standards.

- Our Solution:

Custom modular switchboards with dual-feed inputs, surge protection, and integrated remote diagnostics were designed and tested in-house.

- Result:

The site passed compliance inspections on first attempt and has achieved uninterrupted uptime since launch—enabling rollout of edge services across VIC.

- Challenge: A Tier 3 edge data center needed redundant power feeds, isolated power zones, and real-time monitoring to meet strict uptime and compliance standards.

- Our Solution: Custom modular switchboards with dual-feed inputs, surge protection, and integrated remote diagnostics were designed and tested in-house.

- Result: The site passed compliance inspections on first attempt and has achieved uninterrupted uptime since launch—enabling rollout of edge services across VIC.

Mining

Lithium Processing Plant – WA Pilbara Region

- Challenge:

A lithium processing site required dustproof, vibration-resistant switchboards that could handle high-current loads and extreme temperatures.

- Our Solution:

Pro-Tech delivered heavy-duty switchboards with vibration-dampened mounts, corrosion-resistant powder coating, and external IP-rated panels for control areas.

- Result:

Successful deployment ahead of schedule with full remote commissioning. The plant is now expanding and placing follow-up orders based on performance.

- Challenge: A lithium processing site required dustproof, vibration-resistant switchboards that could handle high-current loads and extreme temperatures.

- Our Solution: Pro-Tech delivered heavy-duty switchboards with vibration-dampened mounts, corrosion-resistant powder coating, and external IP-rated panels for control areas.

- Result: Successful deployment ahead of schedule with full remote commissioning. The plant is now expanding and placing follow-up orders based on performance.

Common Configurations & Custom Options

From mining to renewables, we supply industry-specific boards built for performance and compliance.

Popular Types Include:

1

Solar:

Inverter & grid protection panels

2

Mining:

Heavy-duty IP66 enclosures

3

Commercial:

Group meter & modular boards

4

Industrial:

MCCs & process control panels

5

Data Centres:

Dual-feed & UPS-ready systems

70%+ of our builds are custom-engineered to meet site-specific load, space, and compliance needs.

Our engineers are ready to tailor a solution for your exact needs. From layout design to FAT testing—we handle it all.

FAQs

Industry-Specific FAQs

What standards do your switchboards comply with?

We build to AS/NZS 61439, the current standard for low-voltage switchboard assemblies in Australia, ensuring your board meets all tests for temperature rise, dielectric strength, and short-circuit performance

What is your typical lead time?

Standard panel boards (like DSC, DSE, DSG) are completed within 1–5 days in our express line. Custom high-current or IP66-rated units typically take 2–4 weeks from approval to dispatch.

What is the minimum IP rating for indoor boards?

Indoor boards are supplied with at least IP2X enclosures by default. For outdoor, mining, or solar use, we provide IP66-rated, NATA‑tested heavy-duty enclosures.

Do you perform factory acceptance testing (FAT)?

Yes. Every board undergoes full routine testing—including wiring inspection, insulation checks, mechanical operations, and dielectric tests—according to AS/NZS 61439.

Can a type-tested design be customised?

Yes, but changes may require design verification. We follow AS/NZS 61439 guidelines for “design-verified assemblies” derived from type-tested configurations.

What enclosure IP rating is needed under eaves or verandas?

Under 30° overhangs, IP2X or IP33 is permitted. Otherwise, outdoor enclosures require IP66 to protect against dust and water ingress.

What clearance and access requirements must be met?

Switchboard faces must be at least 1 m clear, with door swing space of 0.6 m on all sides. High-current boards (>800 A or longer than 3 m) require two separate exits.

Do you add RCD protection as standard?

Yes—RCDs are included for all lighting, outlet, and fixed equipment circuits up to 32 A, per AS/NZS 3000 wiring rules

Can switchboards be installed and commissioned after hours?

Yes. We offer evening and weekend commissioning to minimize downtime and ensure smooth implementation with your team.

Is expansion for solar, EV, or future circuits possible?

Absolutely. Our boards are designed modularly—with spare capacity and space—so 70%+ of builds include custom future‑proof configurations tailored to your evolving needs.

Testimonials by Sector

Client Logos

Company Name-1

Company Name-2

Company Name-3

Company Name-4

Company Name-5

Company Name-6

Company Name-7

Need a switchboard built for your site conditions, load requirements, or compliance standards?

Get a Solution Built for Your Industry

We design, manufacture, and deliver switchboards tailored to your industry—whether it’s mining, solar, commercial, or beyond.

Built to Spec. Delivered On Time. Backed by Experts.

Ready to Power Up Your Next Project?

Get a custom-built switchboard delivered on your schedule and built to spec.